BLACKBURNS X-TRUDE PROFILE SYSTEM

18

BXF-50

BXF-75

BXF-100

BXF-150

BXF-200

Manufacture

Guidelines

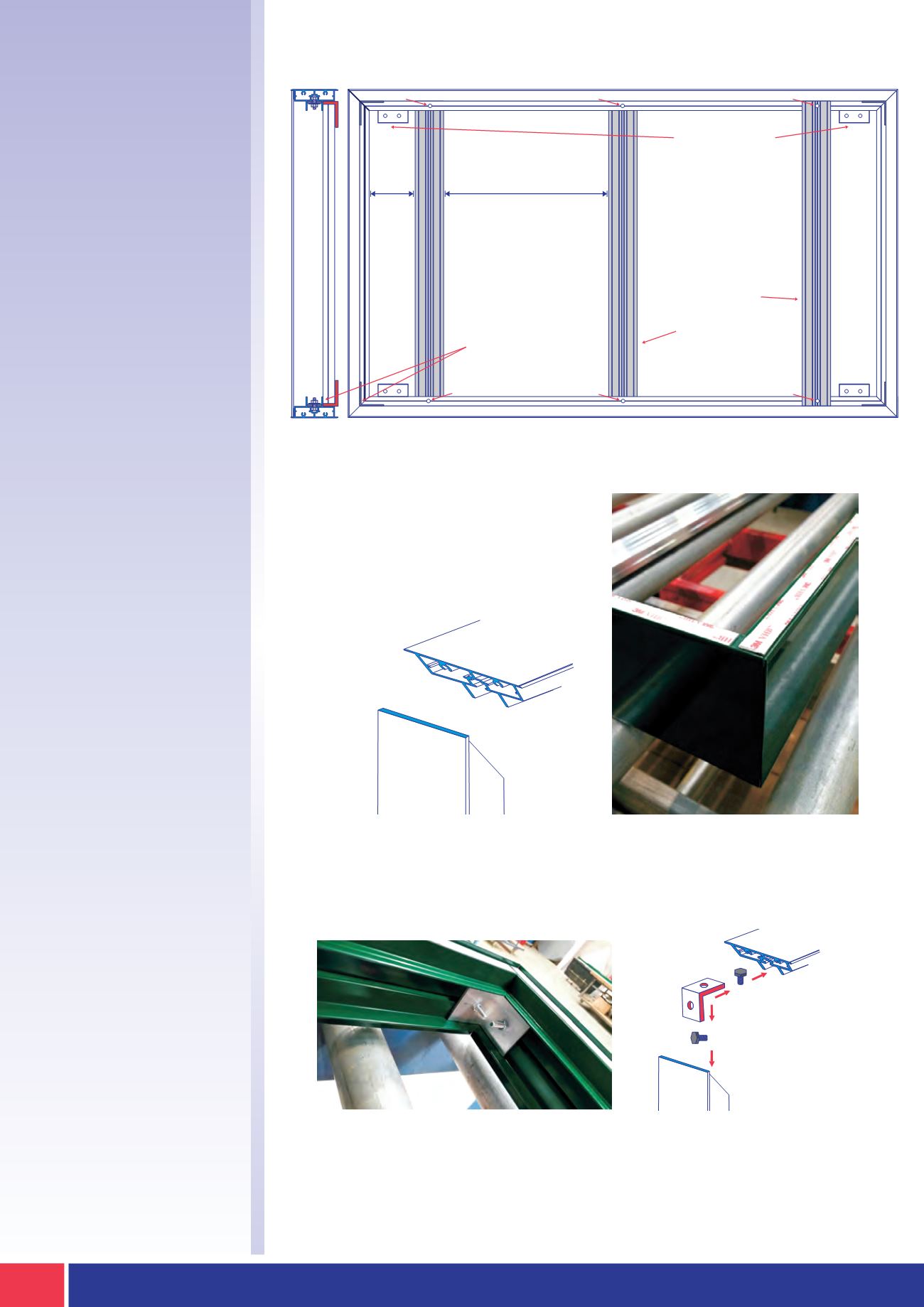

Example Frame

Construction

STAGE 1

Measure & Cut

STAGE 2

Assemble

Outer Frame

Maximum Spacing 750mm

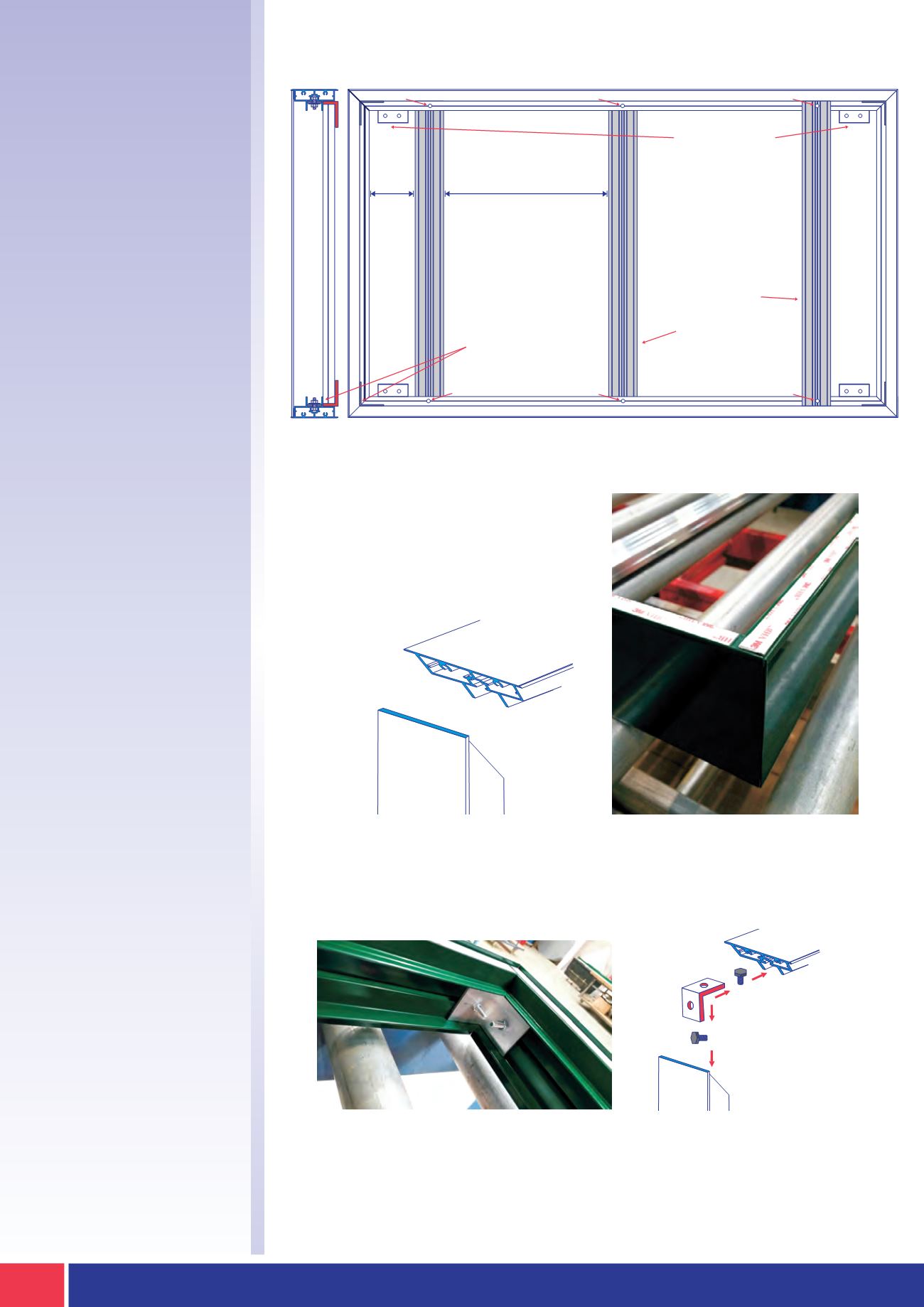

BXF-50 / 75 / 100 / 150 /

200C Pre-cut 50/50 x 3mm

angle cleat bolted into

place using an M6 nut

bolt and washers

BXF-SFB Vertical support

rails to be rivetted to the

outer back edge

and panel joint

supports to the face

Back panel to be notched

to allow for BXF-SFB

fixing brackets if required

Max.

Spacing

350mm

BXF-50 / 75 / 100 / 150 / 200

Outer Frame Extrusion

Rivet

Rivet

Rivet

Rivet

Rivet

Rivet

BXF-50 HAS AN INTERNAL CLEAT WHICH SLIDES INTO THE SAME SLOT AS THE JOINING

STRIP, AND IS RIVETED INTO PLACE, AS THERE IS NO AVAILABILITY FOR M6 BOLT CHANNEL

IN THIS SIZE PROFILE.

When manufacturing the first requirement

is to cut the outside frame (from the profile

BXF-50/75/100/150 or 200) at a 45 degree

mitre at all four corners.

The outer frame is assembled using the matching pre-cut and drilled aluminium

angle corner brackets / cleats. They are secured into place by sliding a standard M6

hex bolt with matching nuts into the provided channel.

EXAMPLE FRAME CONSTRUCTION