BLACKBURNS X-TRUDE COMPONENT & ASSEMBLY GUIDE

19

STAGE 3

Support Section

STAGE 4

Fabricating

Sections

STAGE 5

Tape Application

Hanging Brackets

(if required)

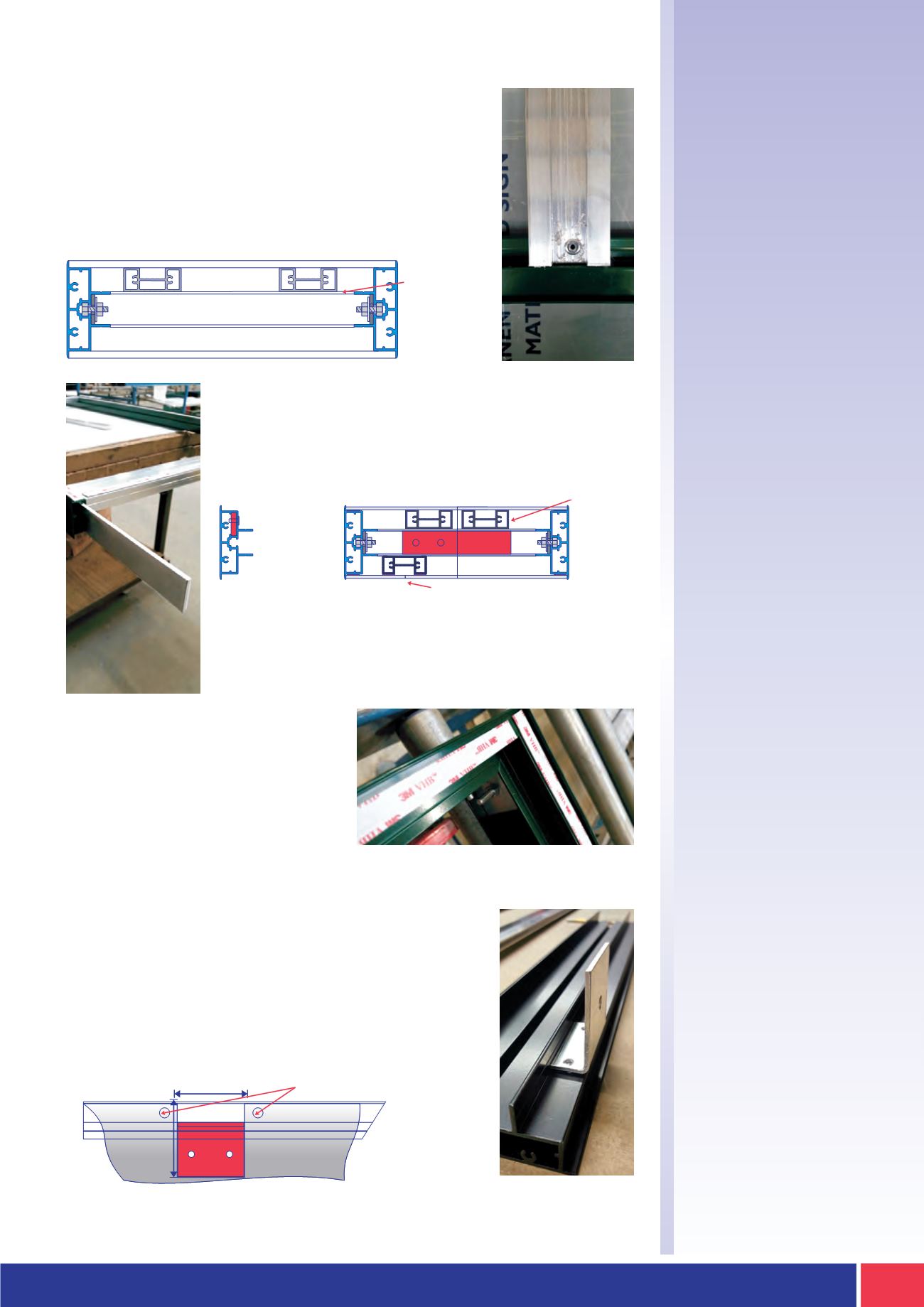

When the frame is fully fabricated it can

then be sent for painting. The frame

should then be primed and a suitable

double sided tape** applied to the

entire perimeter frame.

**

PLEASE CONSULT YOUR TAPE SUPPLIER FOR GUIDANCE ON SELECTING

THE CORRECT TAPE AND APPLICATION PROCESS

BACK PANEL IS SCREWED TO THE

FRAME TO ALLOW FOR REMOVAL

IF REQUIRED

When the outer frame is complete then introduce the BXF-SB

support brace profile. The support profile is attached along the

smallest dimension (width or height) and a minimum of two

supports are required. Additional supports are applied at a

maximum spacing of 750mm. Support sections are cut 37mm

shorter then the overall height/width and are secured in place

along the inside back edge with a rivet fixing.

When a frame is supplied in sections you introduce the

required BXF-JS 5mm aluminium joining strip. The strip slides

into the extrusion frame and is secured with a rivet into one

section only. The second side is secured on site during

installation with a self-tapping screw (if required).

An additional BXF-SB brace is also introduced to the inside

face edge staggered to the frame joint to allow a solid butt

joint in the face panel.

70

65

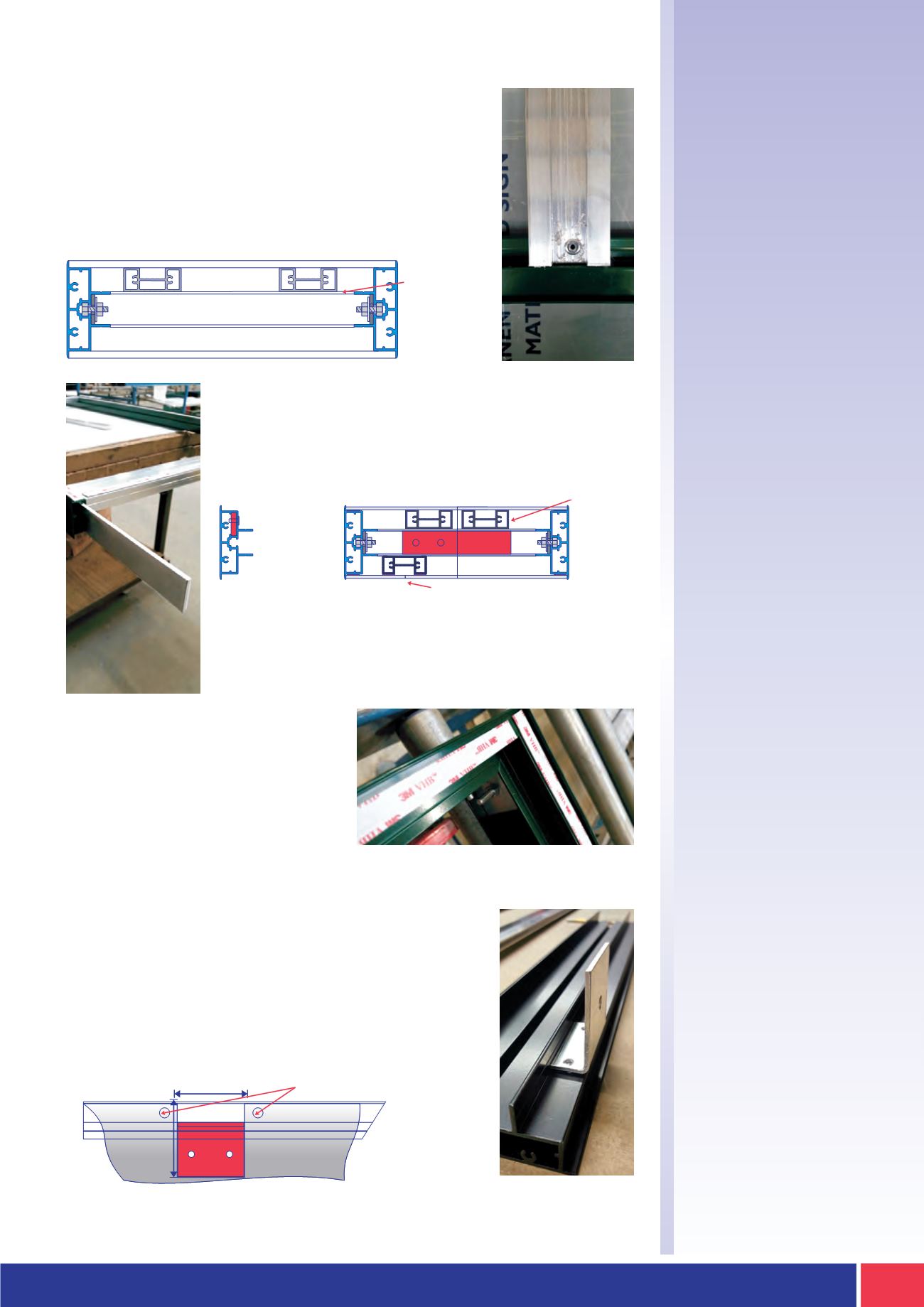

Back Panel

For illuminated frames the back panel is to be screwed into

place to allow for removal, and any required BXF-JS joining

strips are not secured on the second side during installation.

The back panel is also notched around the parameter where

BXF-SFB installation brackets are required. The notch site is

65mm x 70mm.

SUPPORT

SECTION TO

THE REAR OF

INNER FRAME

TO ALLOW

FOR WALL

MOUNTING

LOCATION

WITHIN

EXTRUDED

FRAME FOR

JOINING STRIP

SUPPORT

SECTION TO

THE REAR OF

INNER FRAME

TO ALLOW

FOR WALL

MOUNTING

SUPPORT SECTION TO FACE OF INNER FRAME FOR

PANEL JOINTS TO ALLOW FOR A CLEAN BUTT JOINT