Typical Physical Properties - Alumec 89

®

Thermal conductivity (at 25

o

)

165W/

o

C

Young’s modulus

71 GPa

Coefficient of linear expansion

23x10-6 per

o

C

Compression modulus

73 Pa

Relative density

165W/

o

C

Rigidity modulus

27 GPa

Specific heat capacity

165W/

o

C

Ultimate shear stress

320 MPa

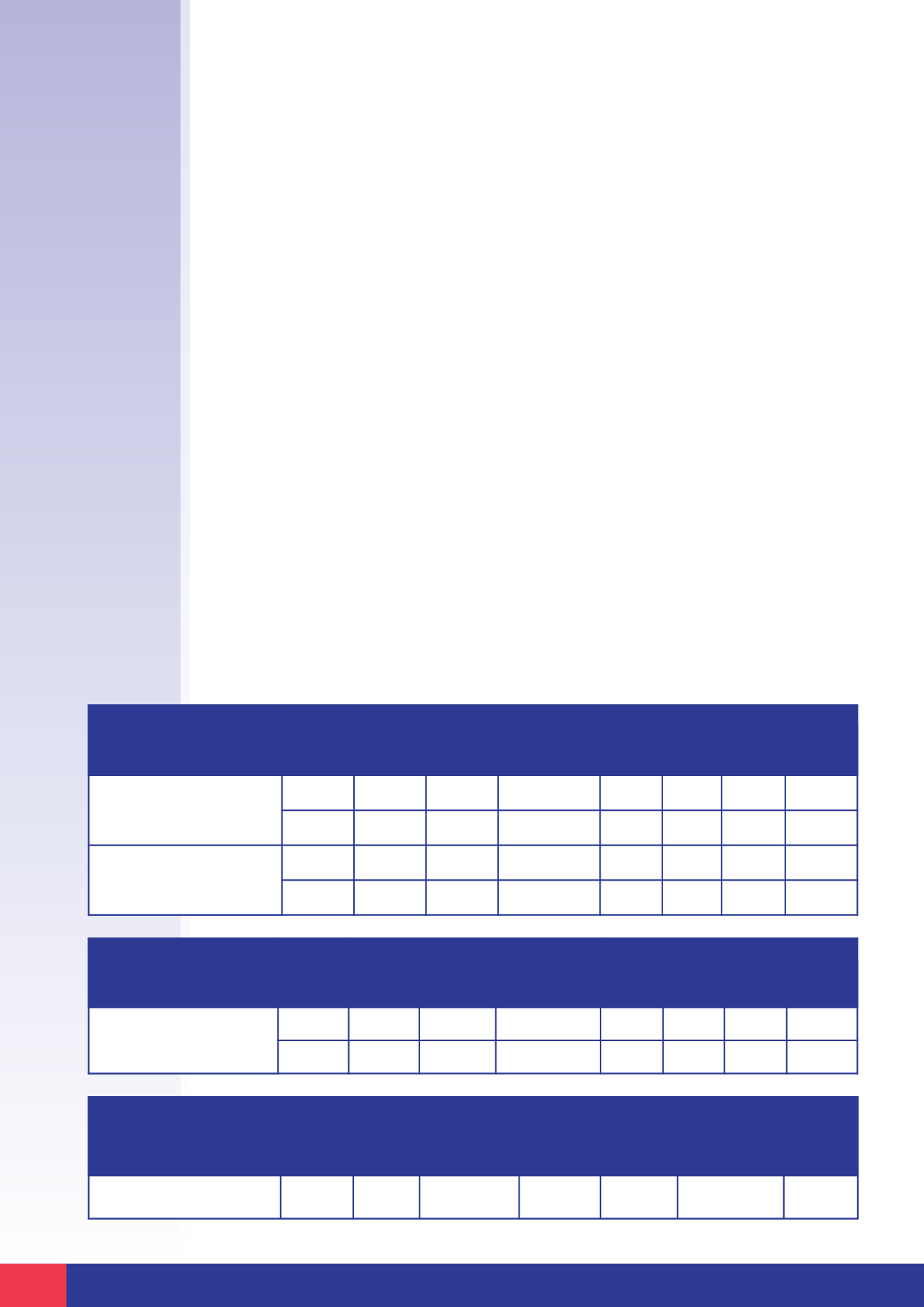

Machinability Data

Machinability factors (K) (in

3

removed per minute per horsepower at cutter)

Source: Tool & Manufacturing Engineers Handbook

(K)

(K)

Aluminium Alloys, Magnesium Alloys

2.5 - 4.0

Forged and Steel Alloy

0.5

Bronze, Brass

Soft

1.7 - 2.5

Free Machining S/Steel

1.1

Medium

1.0 - 1.4

Copper (annealed)

0.84

Hard

0.9

Tooled Steel

0.505

Forged and Alloy Steel

0.63 - 0.87

Titanium

0.75

Process Values

10

s . com

Tech Data

HIGH SPEED STEEL

UNCOATED CARBIDE

Speed

Feed

Tool Material

Speed

Feed Tool Material

Cut Depth

mm m/mm mm/rev

ISO

Brazed

m/mm

Indexable

m/min mm/rev

ISO

TUNING

Toolsteel P20 /

Alumec

®

Top and side rake 5 - 10.

Nose radius 0.25 - 0.40mm

1

1

44

305

0.18

0.18

S4, S5

S4, S5

140

610

175

max

0.18

0.25

P10

K01, M10

8

8

29

245

0.50

0.75

S4, S5

S4, S5

90

365

105

max

0.75

1.00

P30

KP1, M10

BORING

Toolsteel P20 /

Alumec

®

0.25

0.251

43

305

0.075

0.075

S4, S5

S4, S5

130

610

150

max

0.075

0.15

P10

K01, M10

2.50

2.50

23

215

0.030

0.030

S4, S5

S4, S5

73

365

85

max

0.30

0.40

P30

K20, M20

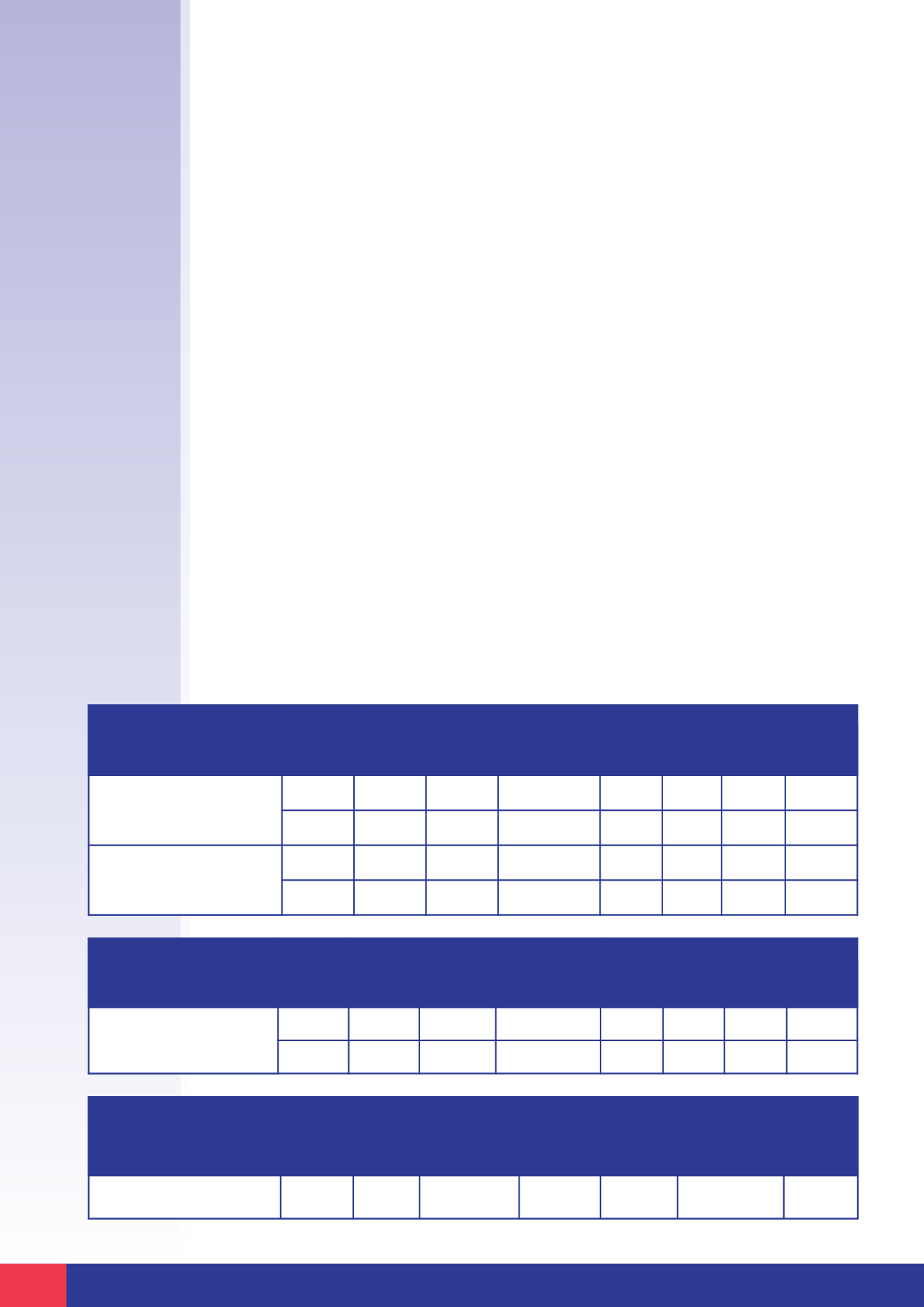

FACE MILLING

HIGH SPEED STEEL

UNCOATED CARBIDE

Speed Feed/Tooth Tool Material

Speed

Feed/Tooth Tool Material

Cut Depth

mm m/mm mm/rev

ISO

Brazed

m/mm

Indexable

m/min mm/rev

ISO

Toolsteel P20 /

Alumec

®

1

1

50

365

0.15

0.25

S4, S2

S4, S2

150

610

170

max

0.20

0.25

CP20

K10, M20

8

8

30

280

0.36

0.50

S4, S2

S4, S2

81

365

100

max

0.40

0.65

CP20

K20, M30

END MILLING

HIGH SPEED STEEL

UNCOATED CARBIDE

Radial

Cut Depth

mm

Speed Feed mm/tooth

Cutter ø mm

10 25-50

Tool Material Speed Feed mm/tooth

Cutter ø mm

m/mm 10 25-50

Tool Material

m/mm

ISO

ISO

Toolsteel P20 /

Alumec

®

0.50

0.50

37

245

0.025 0.102

0.75 0.180

S4

S4, S2

160

395

0.025 0.130

0.075

0.180

P20, M20

K20, M20