11

Aluminium Plate TECHNICAL DATA

Lubrication

Special lubricants are not required for Alumec

®

products. Soluble oils and straight

oils are perfectly satisfactory and give excellent results. pH levels should be

maintained at 6.0 - 8.0. Chlorinated biocides should be avoided.

Electric Discharge Machining

(EDM)

Machine settings are similar to those used for steel, but may need more power to

stabilise. Metal removal rates are 3 to 4 times that of steel necessitating good

flushing to avoid arcing. Copper electrodes give best results and show less wear.

Roughing electrodes are rarely required.

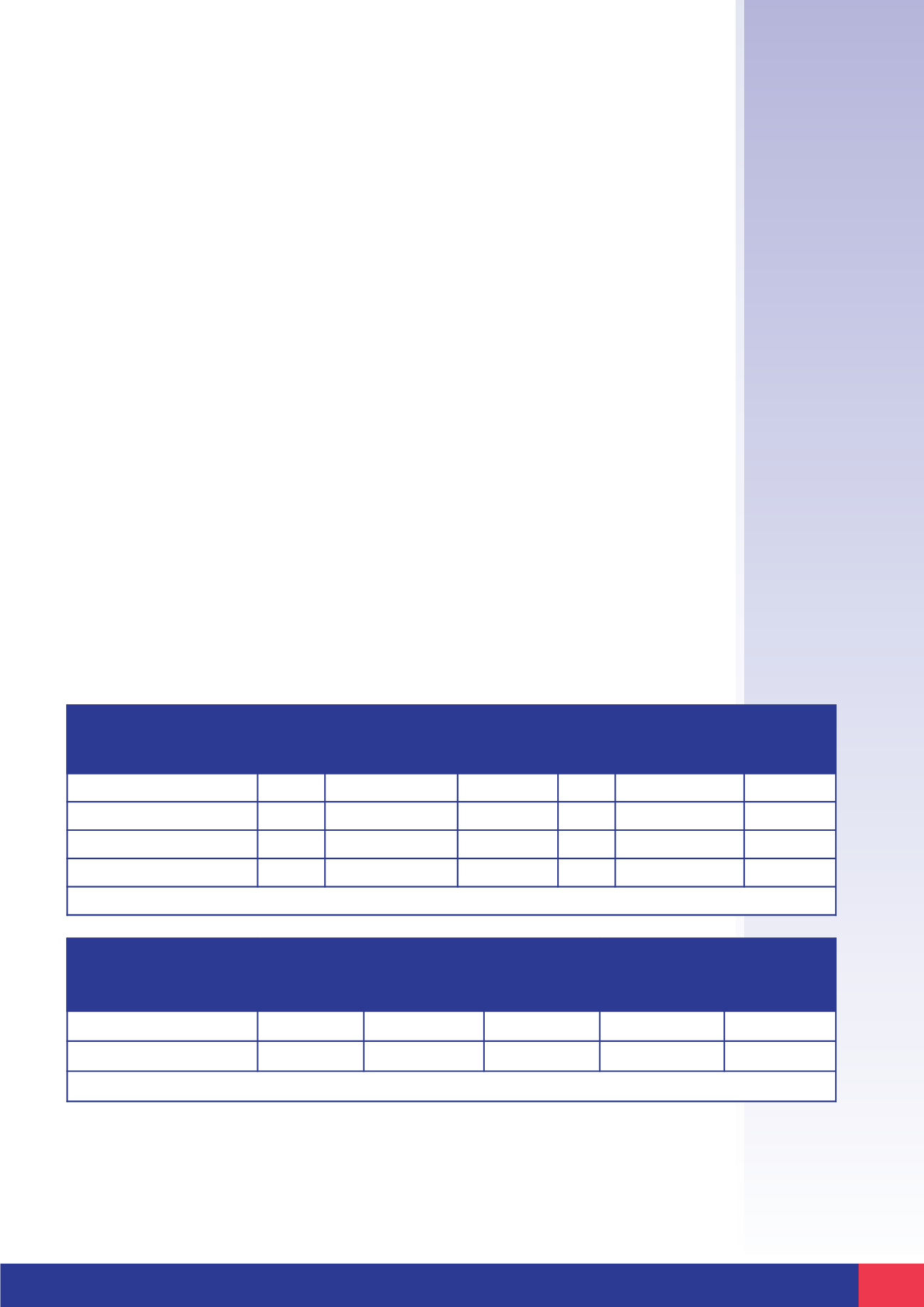

REAMING

HIGH SPEED STEEL

UNCOATED CARBIDE

Roughing

Speed

mm

Feed mm/tooth

Cutter ø mm

3 25 50

Tool Material

ISO

Finishing

Speed

mm

Feed mm/rev

Cutter ø mm

3 25 50

Tool Material

ISO

Toolsteel P20

20 0.10 0.50 0.75 S2, S3, S4, K20

11 0.13 0.50 0.75 S2, S3, S4, K20

Alumec

®

150 0.18 0.50 0.75 S2, S3, S4, K20

55 0.10 0.40 0.75 S2, S3, S4, K20

Toolsteel P20

24 0.10 0.50 0.75 S2, S3, S4, K20

14 0.13 0.50 0.75 S2, S3, S4, K20

Alumec

®

305 0.13 0.40 0.65 S2, S3, S4, K20

76 0.10 0.40 0.50 S2, S3, S4, K20

Based on 4 flutes for 3mm and 8 flutes for 25mm and 50mm Helix angle 10

o

- 15

o

for spiral reamers Radial angle 5

o

- 10

o

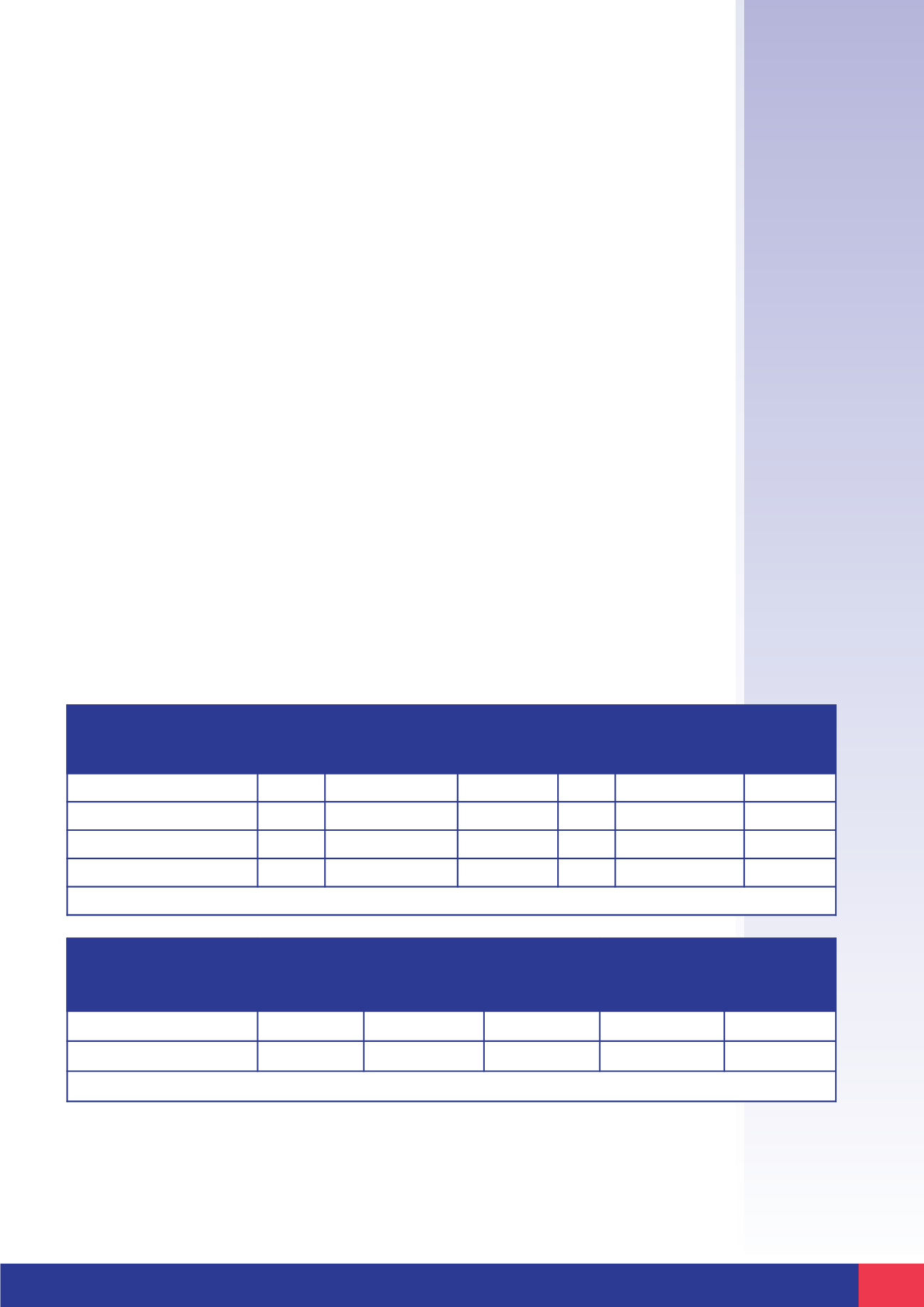

DRILLING

HIGH SPEED STEEL

UNCOATED CARBIDE

Speed

m/mm

1.5

Feed mm/rev

25

50

Tool Material

ISO

Toolsteel P20

18

0.025

0.028

0.45

S2, S3

Alumec

®

43, 84

0.025, N/A

N/A, 0.50

N/A, 0.75

S2, S3, S2, S3

Helix angle 25

o

Point angle 118

o

Lip clearance 12

o

Contact your

local

Blackburns today...

(see back cover for locations and contact details)