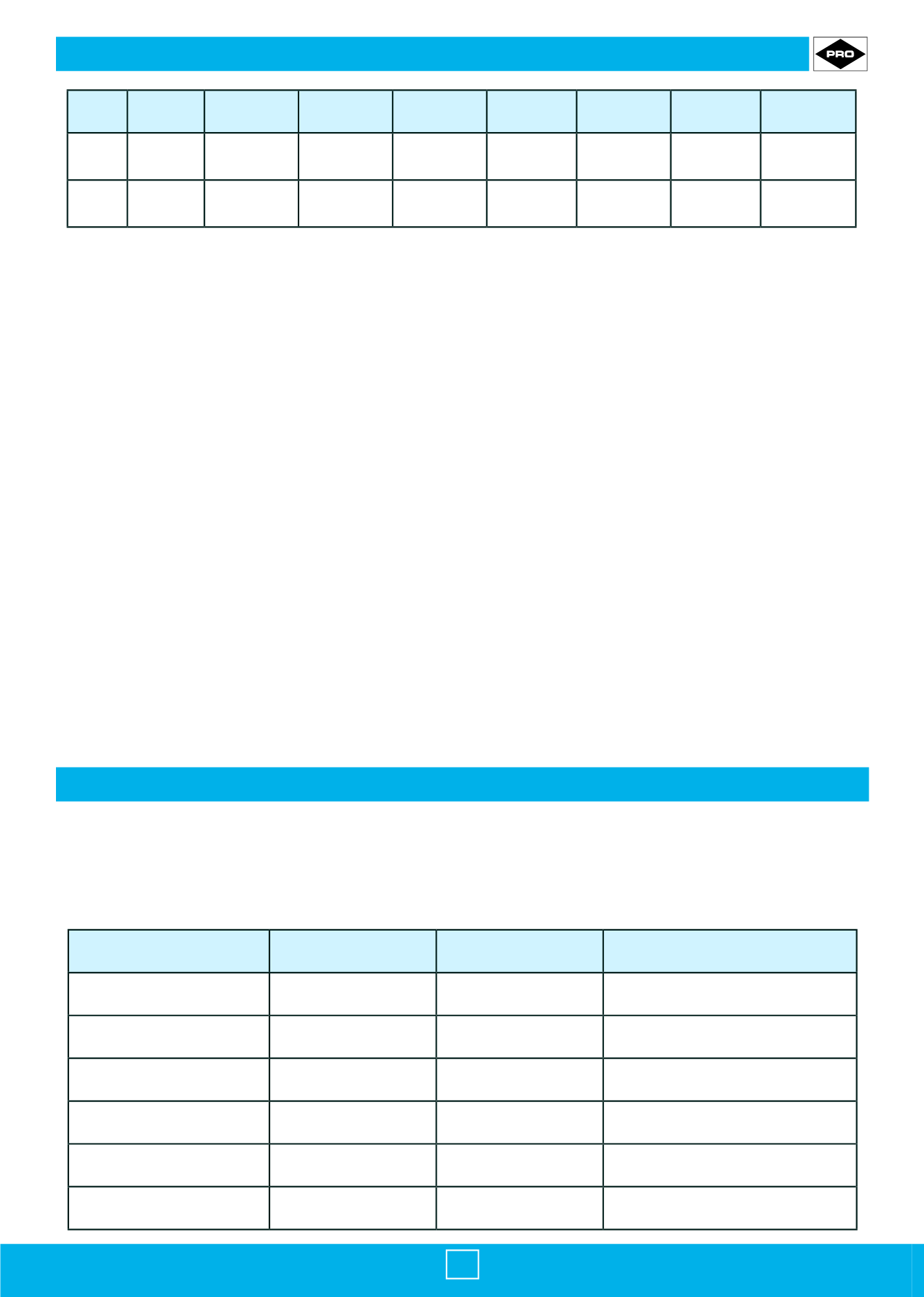

Grade Carbon

Silicon

Manganese Phosphorous Sulphur

Nickel

Chromium Molybdenum

304

DIN

1.4301

<=0.08

<=1.00

<=2.00

<=0.035

<=0.035 8.00 - 10.50 18.00 - 20.00

-

316

DIN

1.4401

<=0.09

<=1.00

<=2.00

<=0.035

<=0.035 10.00 - 14.00 16.00 - 18.00 2.00 - 3.00

Part 1 - 1991

(Sections 1.1 to 1.15 replaced by EN 1088) - This standard specifies the properties of

various stainless steels, and includes a general reference of six mechanically polished surfaces of

different nominal grit sizes.

Part 2 - 1983

(Amended in 1985 &¢1991 and 683/13 Euronorm 88)

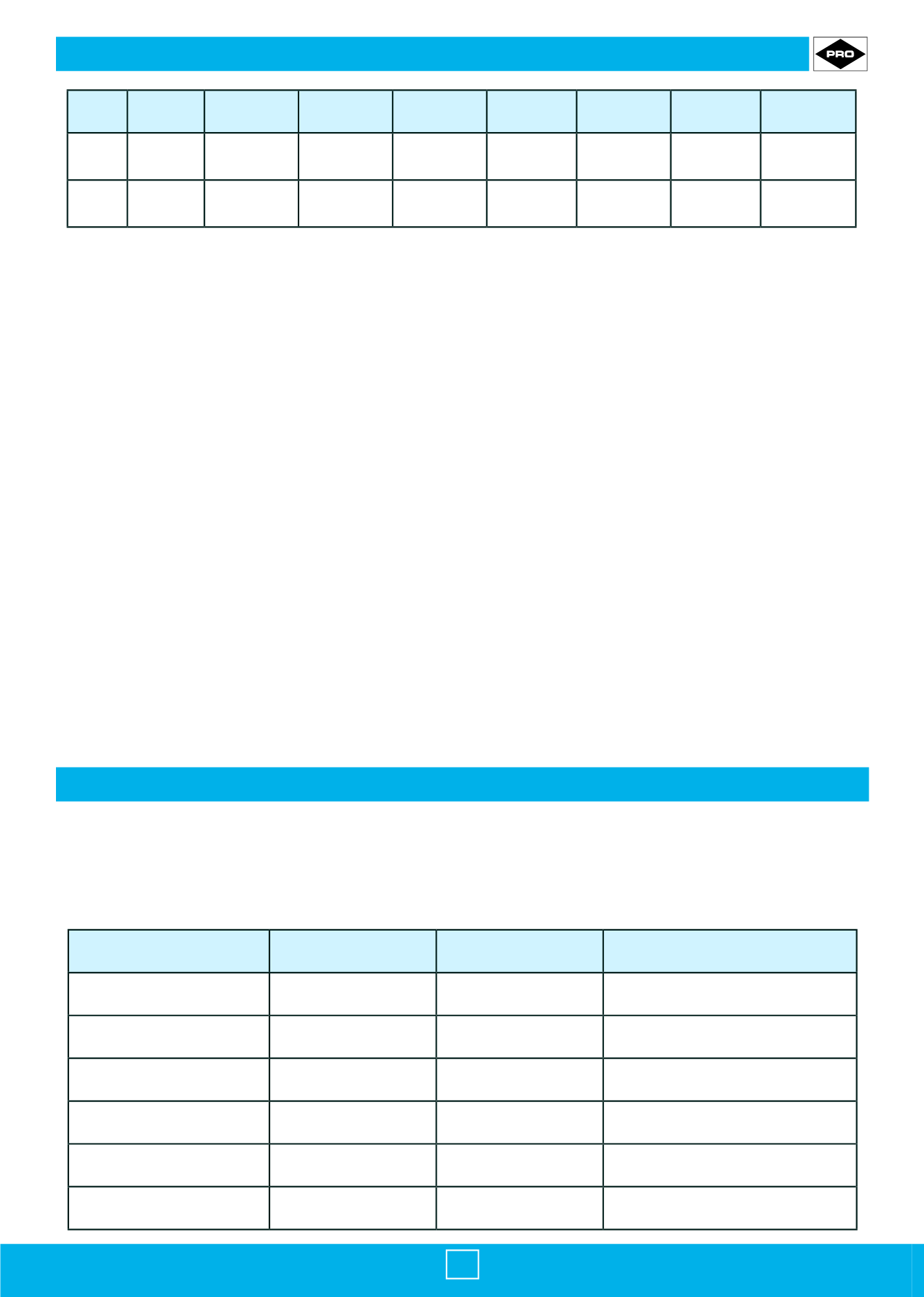

Nominal Grit Size

BS 1449 Pt 2

EN 1088

Description

80 -100

3A

1G/2G

Ground Ra nom 2.5 µm

180

3B

2J

Ground Ra nom 1.25 µm

240

4

1J/2J

Dull Polish Ra nom 0.6 µm

320

5

1K/2K

Satin Polish Ra > 0.5 µm

590 - 630

7

2P

Bright Polish Ra nom 0.05 µm

800

8

1P/2P

Mirror Finish Ra nom 0.05 µm

There are many grades of stainless steel, but the

majority of stainless steel items in this catalogue

are 304 and 316.

Grade 304 is the most common stainless steel,

and satisfies a broad demand for adequate

performance at an affordable price. It has good

corrosion resistance in a wide variety of

environments. It is the best choice for indoor

use (except swimming pools).

Grade 316 has a higher level of corrosion

resistance and is often referred to as marine

grade. Typical applications are architectural

components where they are exposed to extreme

weather conditions and climatic conditions, such

as near the coast, near heavy industrial sites or

in/around swimming pools.

Stainless steel is not maintenance free but

maintenance friendly and when using stainless

steel material outdoors, you need to clean

periodically, especially in aggressive

environments like coastal areas or swimming

pools. The chlorine rich atmosphere driven in

from the sea can affect in-land stainless as far as

20 miles from the coast.

Choosing the correct grade can dramatically

improve the corrosion resistance againstchlorine,

but other things should be taken into

consideration.

Surface finish is a critical element in the battle

against corrosion. The British Stainless Steel

Association (BSSA) recommend that a surface

finish of no less than 0.5µm Ra (320 Grit) is used

on all applications subjected to a chlorine rich

environment. A surface any rougher than this will

retain corrosive particles and rust will inevitably

follow.

STANDARDS RELEVANT TO SURFACE FINISH - BS 1449

54

PRODUCT SELECTION