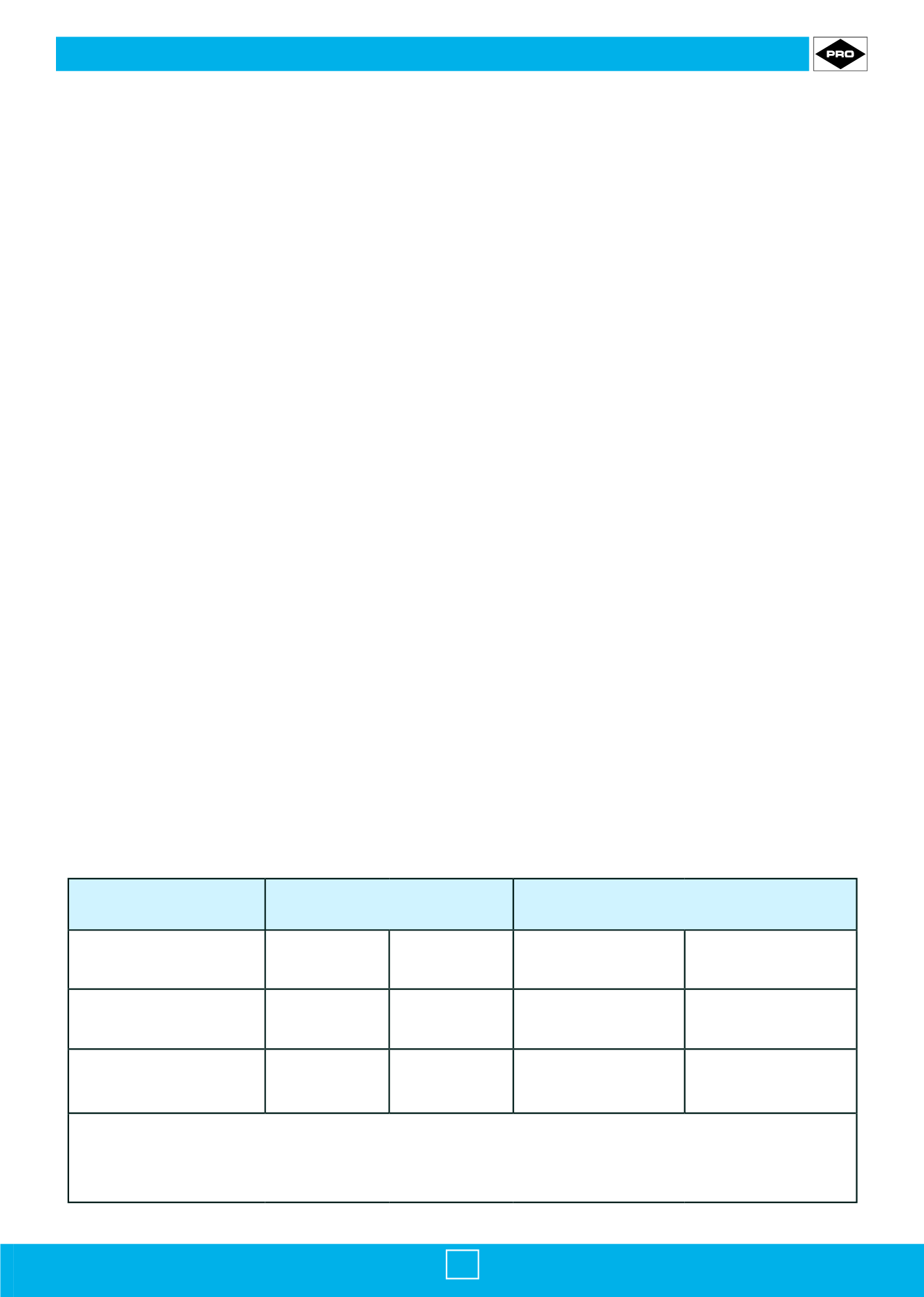

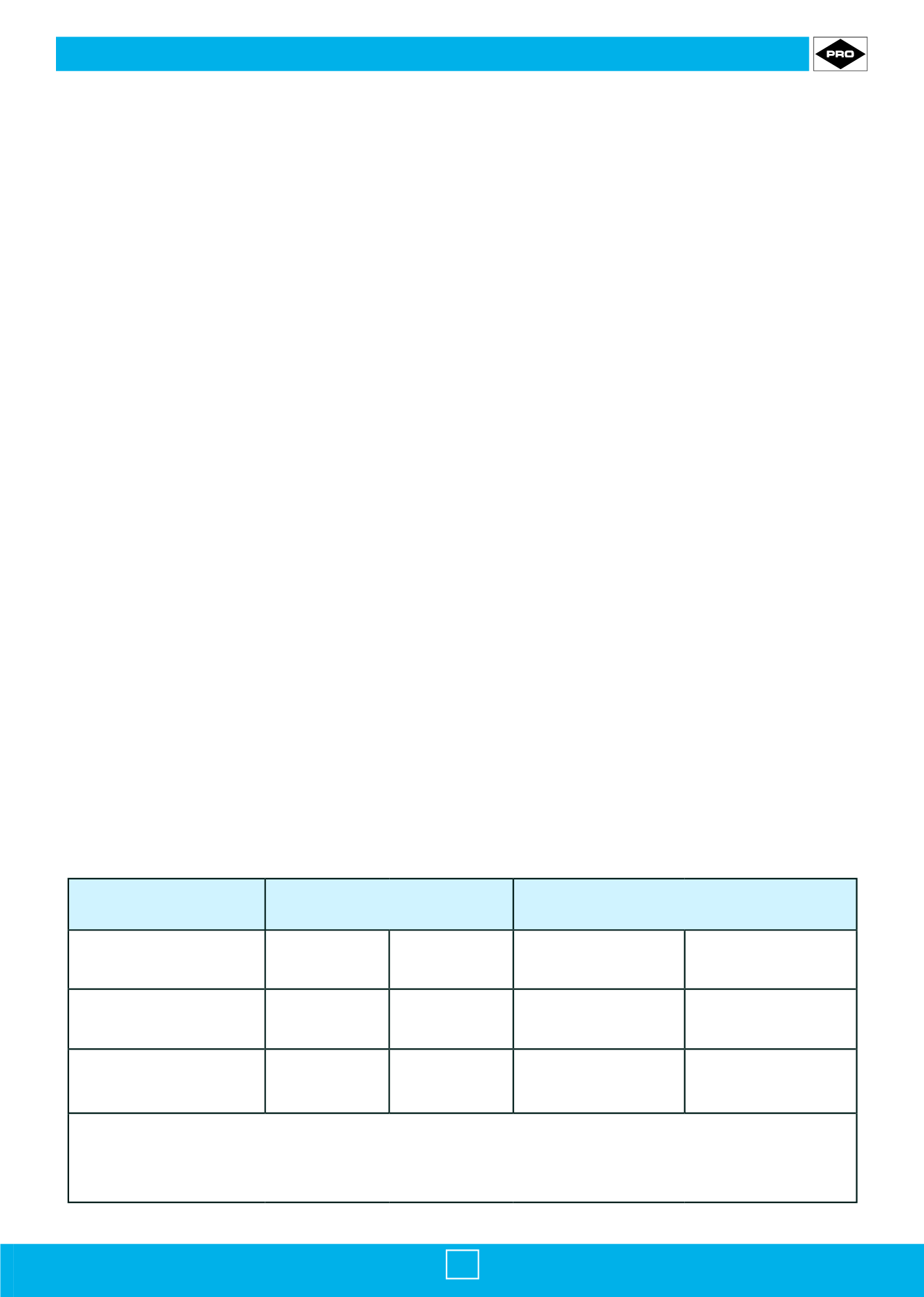

Building

Roof or wall washed by rain

Eaves, Soffits or sheltered

areas not washed by rain

Structure

No deposits

Deposits

accumulate

No deposits

Deposits

accumulate

Cleaning in rural, suburban

and residential areas

4/year

6/year

12/year

24/year

Cleaning for seaside,

industrial and severe areas

8/year

12/year

24/year

52/year

Notes:

* cleaning frequency is dependant on surface finish, design details, environment, cleaning procedure and expectations of performance

** cleaning involves using Pro-Railing Enviro-Shield

(189900902)

- which comprises stainless steel cleaner, demineralised water and

protection spray.

Degreasing

Dirt left on the surface after a fabrication process

can have a serious affect on the corrosion

resistance of stainless steel. Not only will it

prevent the steel from oxidizing, it can contain

corrosive particles, which will start rusting at a

later date.

Pickling

Pickling requires the use of strong chemicals

(hydrofluoric acid and nitric acid) to dissolve the

surface of the steel. This process completely

removes any surface contaminants and will help

to restore the chromium level to the weld affected

areas.

The heat from the welding process drives

chromium away from the weld area. The area

adjacent to the weld is often low in chromium and

high in iron. These areas are always the most

susceptible to corrosion once the component is in

use.

Iron dissolves more readily than chromium,

therefore, the pickling process leaves the surface

chromium-rich and in a condition where it can

form a dense oxide layer.

Passivation

Stainless steel will passivate in the open

atmosphere - assuming that it is spotlessly clean

to begin with and so is the air it is sat in. It is a

slow process and, depending on the grade of

stainless, can take between 24-48 hours to occur.

Stainless steel is not self-cleaning!

The chromium-oxide layer that protects stainless

from corrosion is relatively fragile. It can be

broken or damaged during fabrication, if

scratched and/or surface contamination is

allowed to settle on the surface.

The most effective way to form the passive layer

is to force it by subjecting the steel to an oxidizing

chemical. These are typically acid solutions

containing nitric acid or citric acid. This process

speeds up the reaction time and typically takes

around 2-3 hours contact time to fully form a

dense and effective layer.

Simply cleaning a corroded piece of stainless

steel with a stainless steel cleaner and a scouring

pad (usually phosphoric acid or citric acid based)

does not passivate it. These acids will help to

dissolve the corrosion (iron oxides) and leave the

surface in a condition in which it can

self-passivate.

Rain washing regularly will reduce the risk of tea

staining (brown discolouration). This is a visual

impairment only, and does not affect the structural

integrity or longevity of the material. The best way

to prevent it is to follow the cleaning chart below,

but as a general rule of thumb the recommenda-

tion is that the stainless needs cleaning as often

as the glass.

Remember bad design can result in poor

performance e.g. partially sheltered systems will

greatly reduce the benefit of natural washing by

rain. Maintenance of stainless steel should be

considered in the design process.

Recommended cleaning intervals for stainless steel handrail systems

55

CLEANING INTERVALS