29

Code

Size mm

Description

185900201

2440 x 1220 x 4

Templating sheet

Width (W)

Height (H)

Width (W)

Height (H)

Width (W)

Height (H)

Use this guide for ordering make-up panels to match our standard panels and complete your installation.

Where our standard panels cannot be used, we can offer costs for the

production of fully bespoke panels if required.

Our bespoke panels can be:

• Toughened and laminated

• Produced in any shape using state-of-the-art CNC machines

• Produced from many different types of glass

• Coloured or curved

• Drilled and notched

• Made to suit almost all applications

We can provide suitable templating material that can be cut to suit any special

shapes on site and sent to our processors for production to match the template

exactly, using modern imaging scanning technology to duplicate your design.

Price and availability for bespoke panels are available on request.

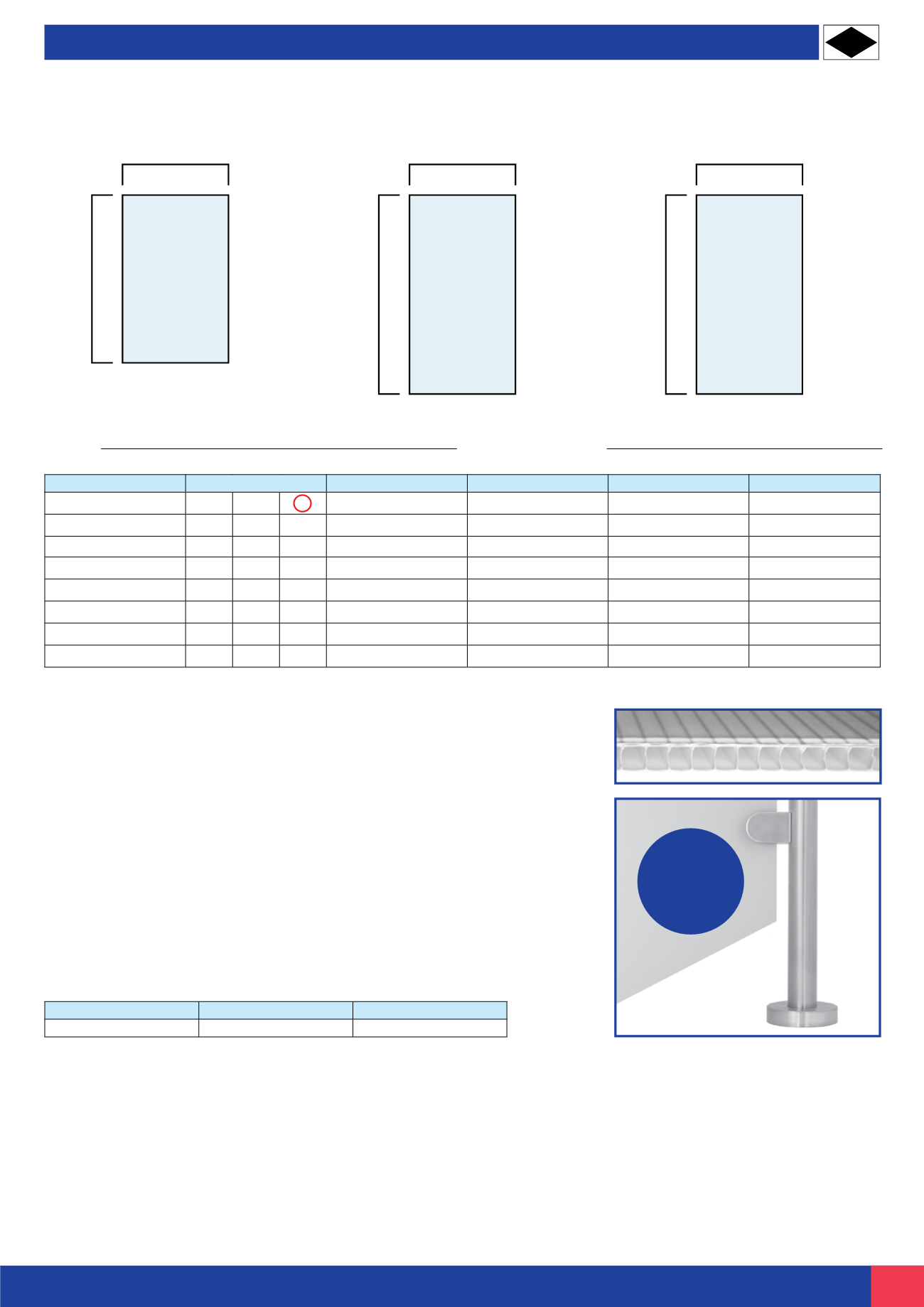

PANEL A

10mm Toughened

Monolithic Clear Float Glass

PANEL B

15 & 19mm Toughened

Monolithic Clear Float Glass

PANEL C

17.5 & 21.5mm Toughened and

Laminated Clear Float Glass

Templating

sheet

Complete as required and return to your local sales office for processing

Ordering Guide:

Name:

Contact Number:

Panel Reference

Panel Type

Glass Thickness

Panel Height

Width Required

Quantity

Example

A B C

21.5

1075

830

2

1

A B C

2

A B C

3

A B C

4

A B C

5

A B C

6

A B C

7

A B C

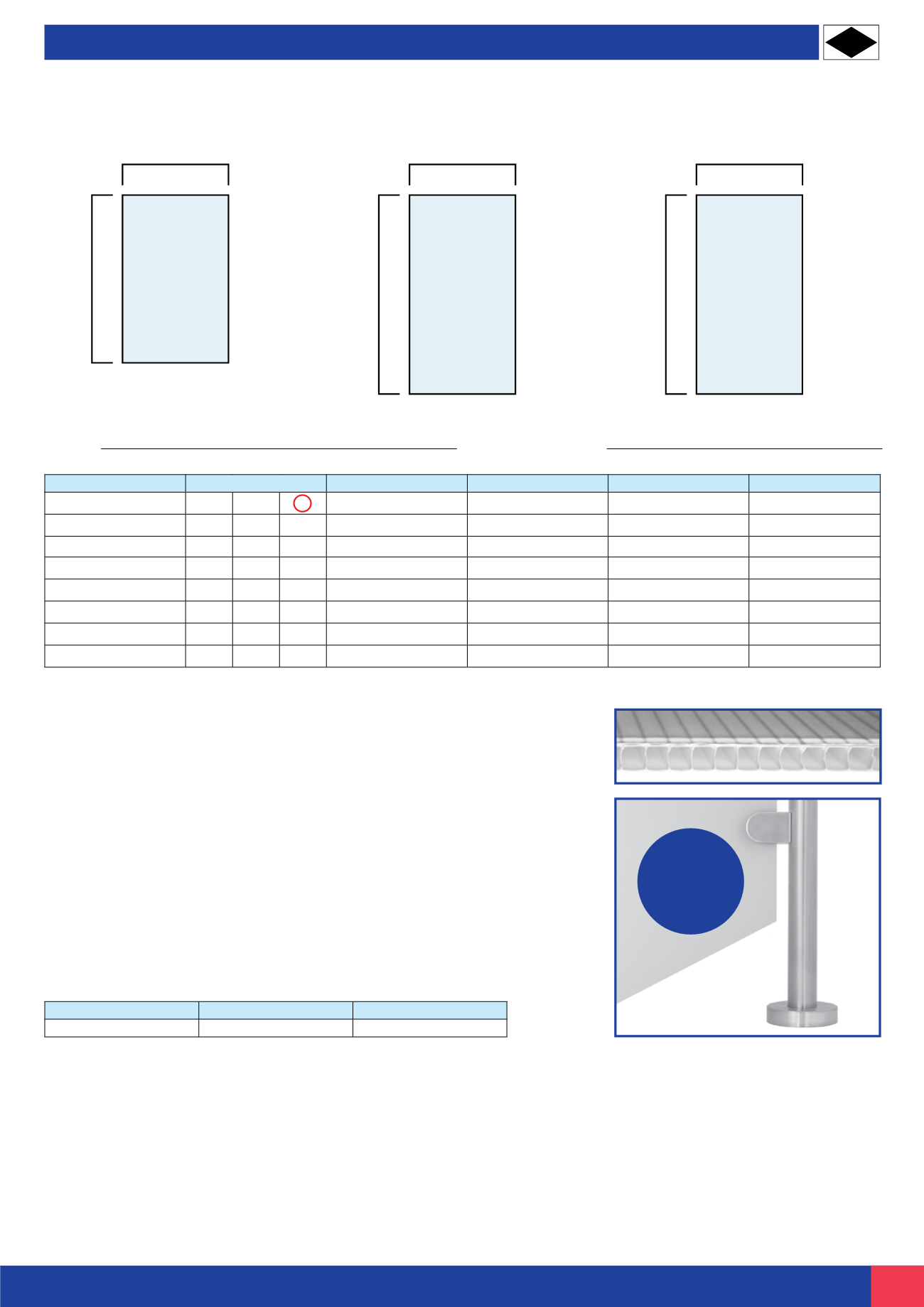

Advice on Fitting Glass

Where a run of glass is made up of multiple panels, we recommend spacing between panels of 25mm.

The reasons for this are:

• 25mm is wide enough for most fingers to pass through easily without getting trapped

• Lining up the glass is much easier, as the smaller the gap, the more noticeable a small +/- difference becomes

PRO-GLASS – Non-Standard PANELS